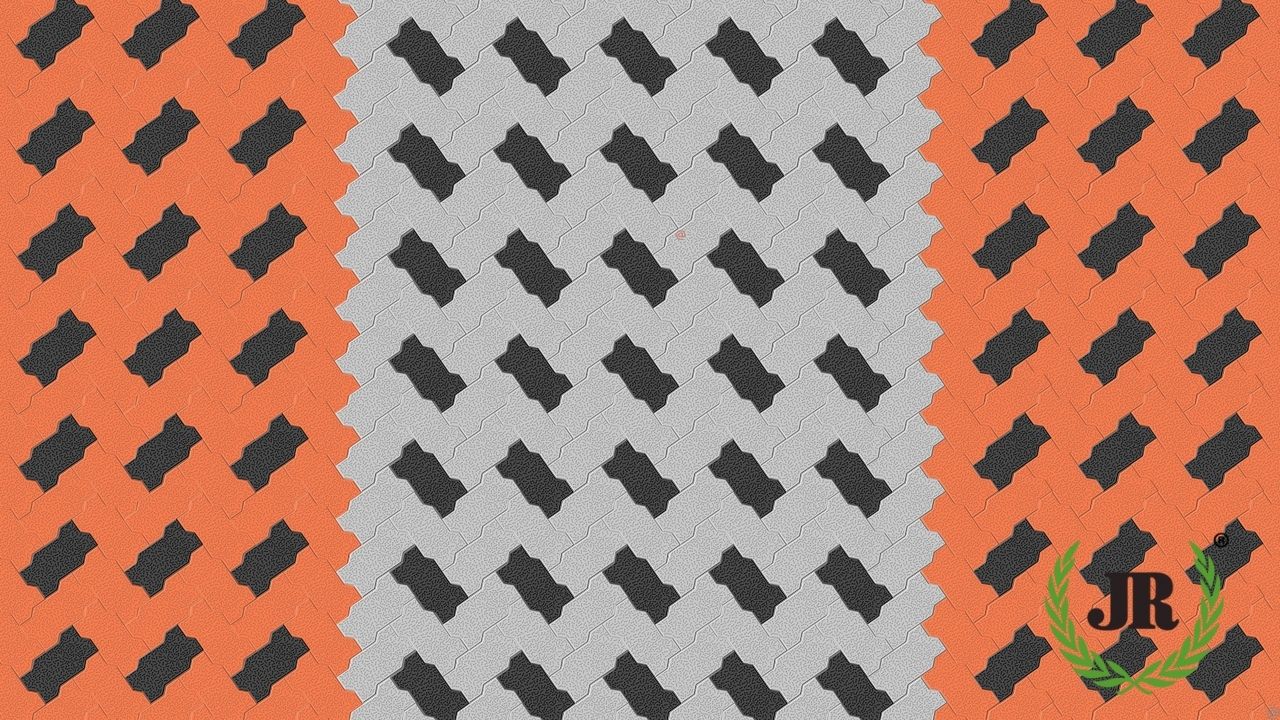

Interlocking paver blocks have changed the worlds of landscaping .These blocks are designed to interlock, creating a sturdy surface that can hold heavy loads and environmental pressures. The result is a well-structured pavement that enhances the beauty of your outdoor spaces and provides functional benefits such as improved load distribution, durability and resistance to movements.

JR Rubber Industries manufactures the best quality paver block moulds. We have contributed to all aspects of paver production including machines, moulds, raw materials, cutting technology, chemicals and colour oxides for paver blocks. We always maintain high quality in our products and reflects in the consistently high demand for what we offer.

Types of Moulds For Interlocking Paver Blocks

The material used in paver moulds plays a crucial role in determining the quality, durability and performance of the pavers produced. Additionally, the material should exhibit dimensional stability to ensure uniformity in the final product and resist temperature variations.

We have mainly three types of interlocking paver moulds:

1. Rubber Moulds Paver Blocks

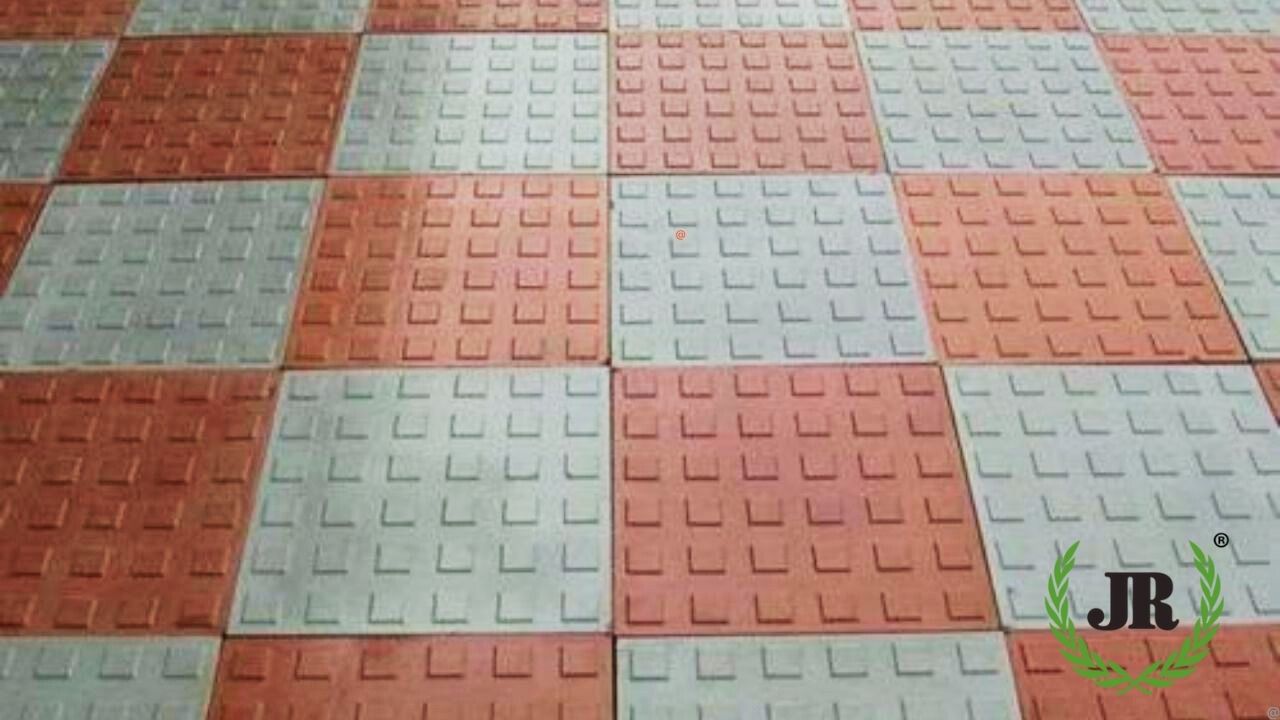

The moulds are made of high-quality rubber allowing for easy creation of interlocking rubber mould pavers. The flexibility of the material helps to create a flawless design and adapt various designs and shapes. Rubber pavers are easy to install making them a popular choice for walkways, patios, and playgrounds.

JR Rubber Industries offers a diverse range of paver block tile designs. Our catalog covers a wide array of shapes and styles to suit different landscaping needs. We specialize in crafting customized moulds to meet specific requirements.

Some of the designs such as paver rubber mould , grass paver rubber mould , curb stone rubber mould , floor tile rubber mould etc

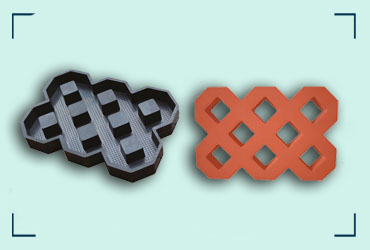

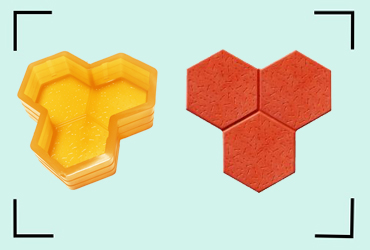

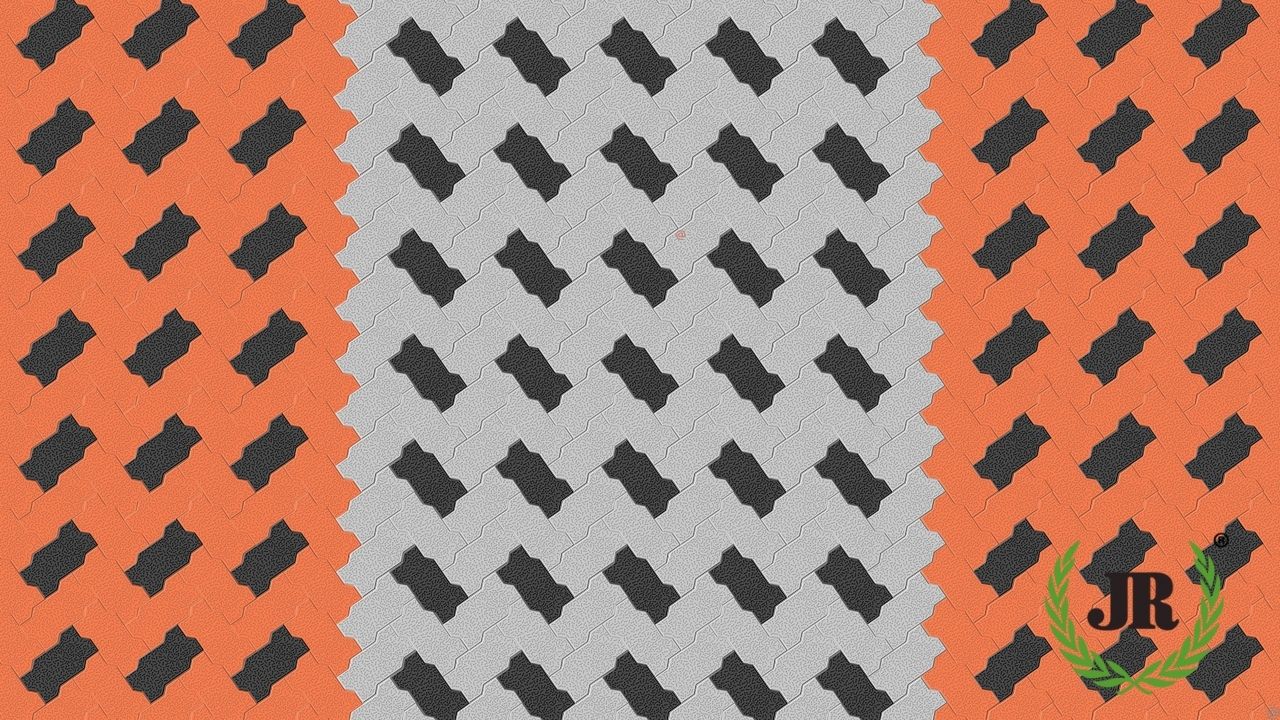

2. PVC Paver Blocks Moulds

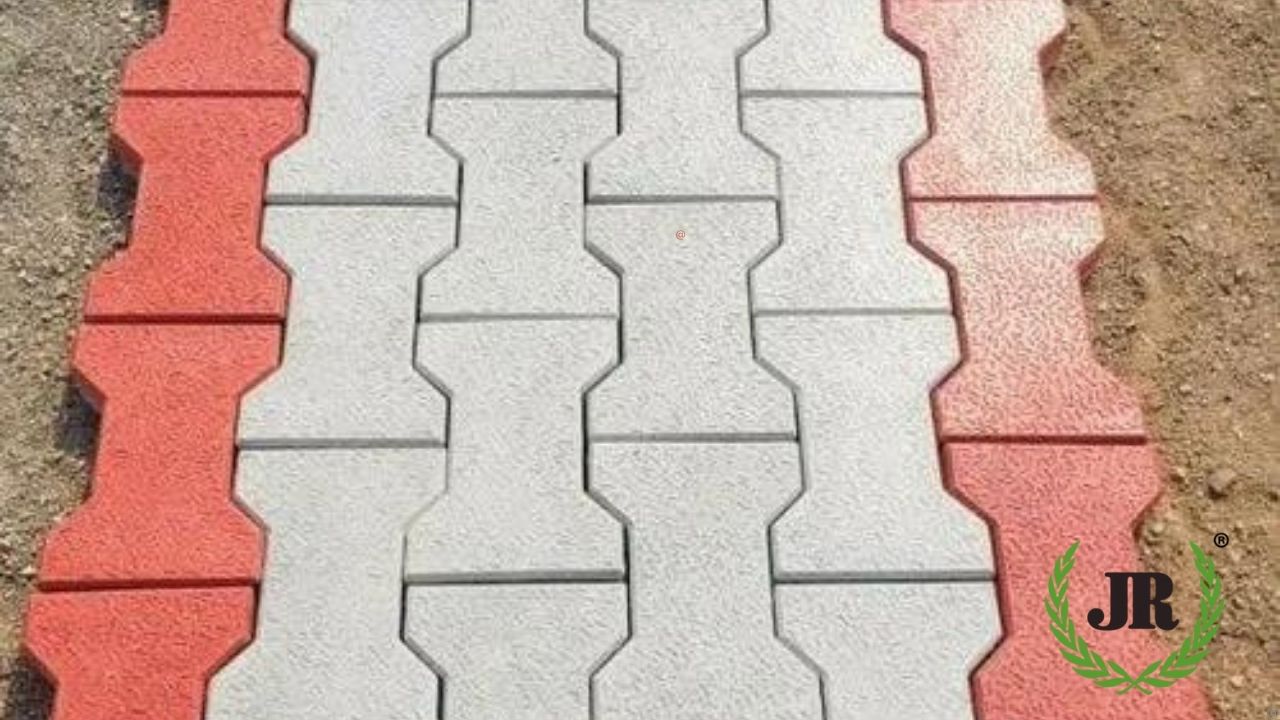

PVC paver molds are used to create concrete or brick-like patterns for outdoor flooring. These molds are made from durable PVC material, allowing for easy demolding and reuse. They come in various designs and sizes, offering versatility in creating different patterns for your pavers. One of the features of PVC paver mould is their flexibility which allows the making of detailed designs. This flexibility makes it possible to create a wide range of paver shapes and patterns. The moulds are easy to work with providing a user-friendly solution for paving projects. Some of the designs of JR Rubber Industries such as zig-zag pvc paver mould, ,i shape pvc paver mould, t series pvc paver mould , hexagon pvc paver mould etc

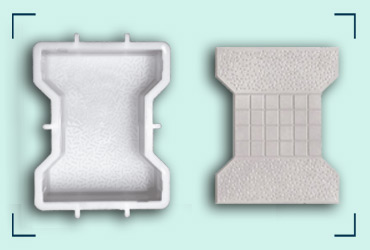

3. Plastic Paver blocks Moulds

As these moulds are crafted from premium-quality plastic material, they are an alternative to traditional pavers. At JR Rubber Industries they are manufactured exclusively using 100% raw material and different shapes and designs. They are lightweight and easy to handle. The lightweight factor of plastic mould also makes the demoulding process easier. Some of our plastic paver moulds Such as plastic squares, plastic elegance ,plastic dumbels ,plastic natural stone etc

Advantages Of Paver Blocks

1. Durability: Interlocking pavers are known for their durability and ability to hold heavy loads making them suitable for such areas i.e driveways and walkways. The strength comes from the interlocking design making it a strong and solid surface.

2. Versatility in Design: One of the key advantages of interlocking pavers is their versatile designs. They come in various shapes, sizes, colours which help in making creative patterns. This helps to aesthetic preferences and requirements of a particular project.

3. Easy Installation and Repairs: Interlocking pavers are designed for easy installation . The interlocking of these paver block tiles reduces the need for traditional materials making installation and maintenance easy. If any paver becomes damaged it can be easily replaced without disturbing the surrounding area. This modularity simplifies maintenance and repairs.

4. Improved Drainage: The gaps between the pavers allow water to drain through them thereby reducing the risk of flooding and formation of paddles on pavers. This feature is particularly beneficial in areas with heavy rainfall, as it helps manage water efficiently and prevents the forming of puddles on pavers.

5. Enhanced Safety: Interlocking pavers often provide a textured surface offering better friction and reducing the risk of slips and falls. This is especially important in areas prone to rain or ice where maintaining a safe walking or driving surface is crucial.

6. Increased Property Value: The aesthetic appeal and functional advantages of our pavers can enhance the appeal of a property ultimately increasing its value.

Maintenance Tips

- Regular cleaning- Sweep or use a leaf blower to remove dirt, leaves, and debris regularly. This prevents the growth of weeds and algae between the pavers.

- Weed control- Inspect the joints between the pavers for weed growth. Use a suitable weed killer or manually remove weeds to maintain a neat appearance.

- Pressure washing- Periodically pressure wash the paver surface to remove accumulated dirt, stains, and moss. This helps restore the original color and appearance.

- Sealing- Consider applying a sealer to the paver surface. Sealing helps protect against stains, enhances color and makes it easier to clean.

- Stain removal- Promptly clean any spills or stains on the pavers. Use a mild detergent or a specialized paver cleaner to avoid discoloration.

- Inspect for damaged pavers- Regularly inspect for any cracked or damaged pavers. Replace these promptly to maintain the integrity and appearance of the overall pavement.

Applications Of Interlocking Blocks

We invite you to explore the intricate patterns, vibrant colors and innovative arrangements that define our block paving. Whether you are seeking inspiration for a residential project, urban development or commercial space our gallery is designed to spark ideas and demonstrate the transformative power of designs.

Driveways: They can withstand the weight of vehicles and provide a durable and attractive surface.

Patios: The interlocking system makes the patios stable and easy to install.

Walkways and Pathways: They provide a stable and non-slip surface for pedestrians.

Pool Decks: The pavers are resistant to water damage and can create a visually appealing area around a pool.

Garden Borders: Pavers are used to create borders around gardens or define different sections in a landscape.

Public Spaces: Interlocking pavers are opted in public places for their versatility and ability to tolerate heavy foot traffic.

Commercial Pavements: Pavers provide a surface capable of handling heavy machinery and vehicles.

Conclusion

With a diverse client base covering India and 34 countries globally, our expertise extends to establishing over 1600 paver units within India and 72 units internationally. Since our industries start in 1993, with 29 years of experience, we have emerged as trendsetters in manufacturing top-tier moulds. Specializing in end-to-end solutions, we empower businesses and entrepreneurs to establish thriving paver factories.

Interlocking paver blocks can be used in driveways, walkways, patios and commercial spaces making them a perfect solution for anyone seeking a balance between form and function. In the grand design of pathways, they are the rock stars. They don’t just connect, they groove together, turning the ground into a dance floor.