Floor Tiles

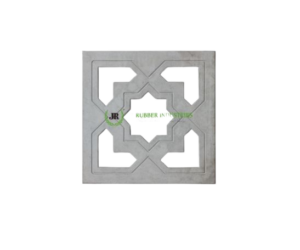

Floor Tiles Rubber Paver Mould Design

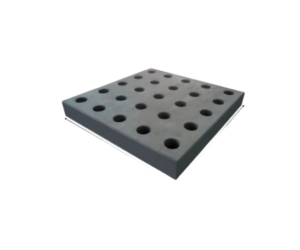

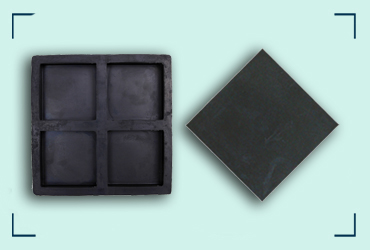

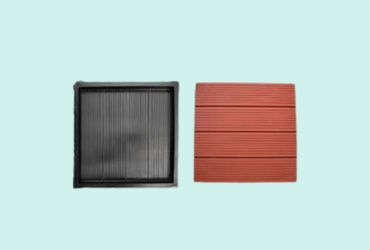

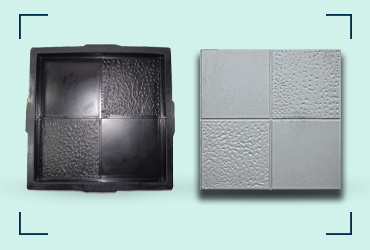

TM 368 COMBOTILE

View More

Enquiry

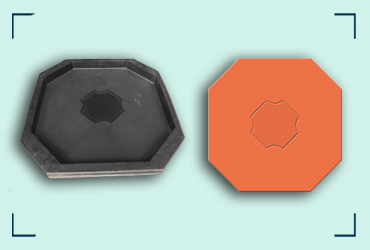

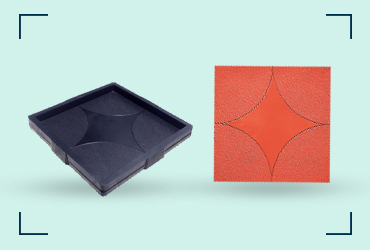

TM 41 Droplet

View More

Enquiry

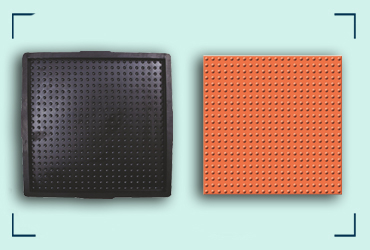

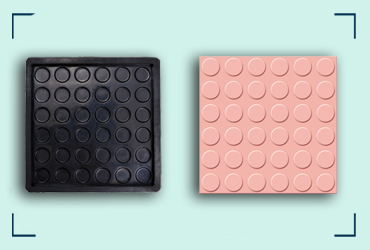

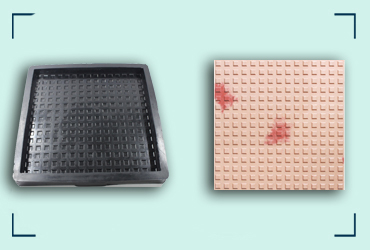

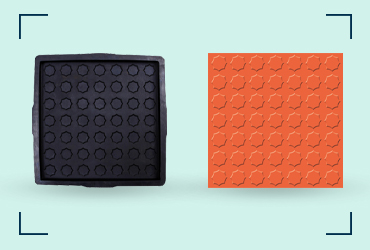

TM 1 Small Button

View More

Enquiry

TM 2 Chakra

View More

Enquiry

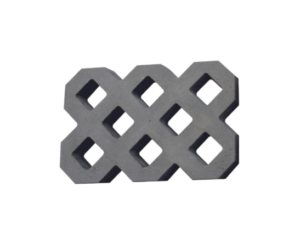

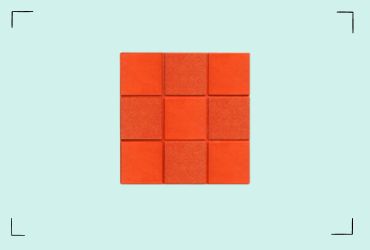

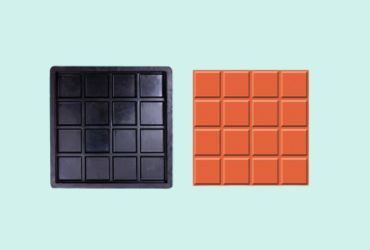

TM 3 Six Checks

View More

Enquiry

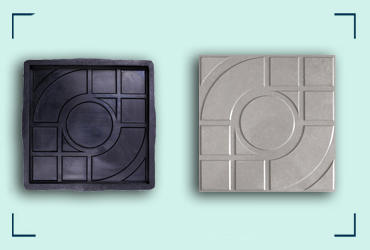

TM 4 Cyclo

View More

Enquiry

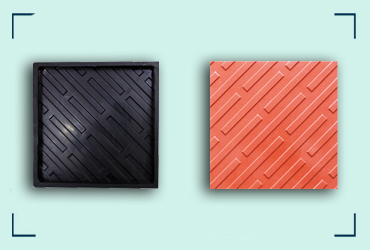

TM 8 Arrowcon

View More

Enquiry

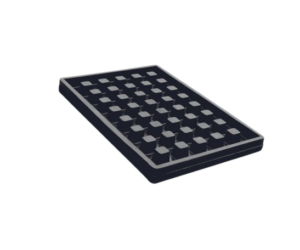

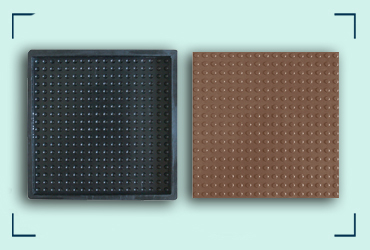

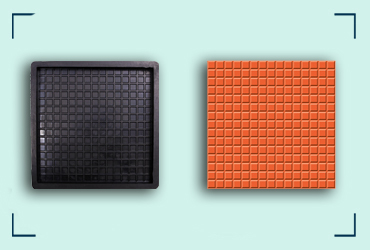

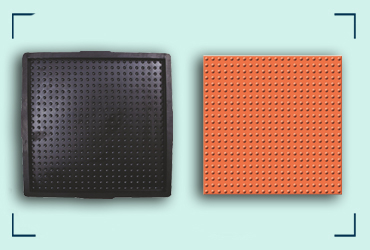

TM 9 Micro Check

View More

Enquiry

TM 10 Spectra

View More

Enquiry

TM 5 Combo

View More

Enquiry

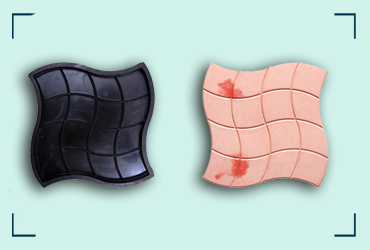

TM 6 Thankam

View More

Enquiry

TM 19 Ajantha

View More

Enquiry

TM 22 Six Rounds

View More

Enquiry

TM 27 Gripper

View More

Enquiry

TM 33 Delta

View More

Enquiry

TM 36 Coral

View More

Enquiry

Pluto

View More

Enquiry

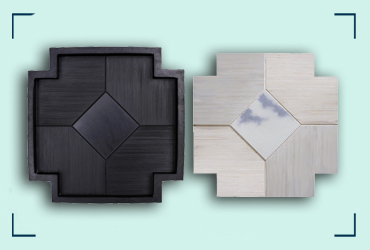

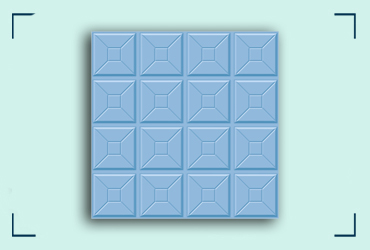

Castle

View More

Enquiry

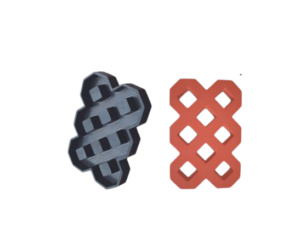

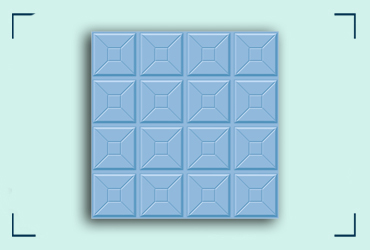

Four Checks

View More

Enquiry

Droplet

View More

Enquiry

Micro Check

View More

Enquiry

Ellora

View More

Enquiry

Masaba

View More

Enquiry

Ajantha

View More

Enquiry

Arc

View More

Enquiry

Chakra

View More

Enquiry

Brook

View More

Enquiry

Helix Tile

View More

Enquiry

Lumino

View More

Enquiry

Narmada

View More

Enquiry

Nebula

View More

Enquiry

Optima

View More

Enquiry

Rado

View More

Enquiry

Sahara

View More

Enquiry