Home > Compound Walls

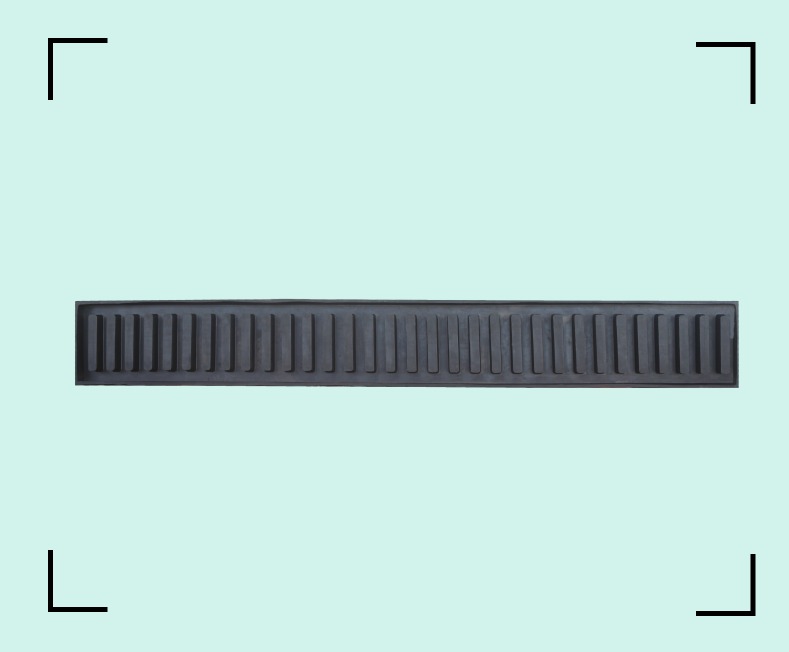

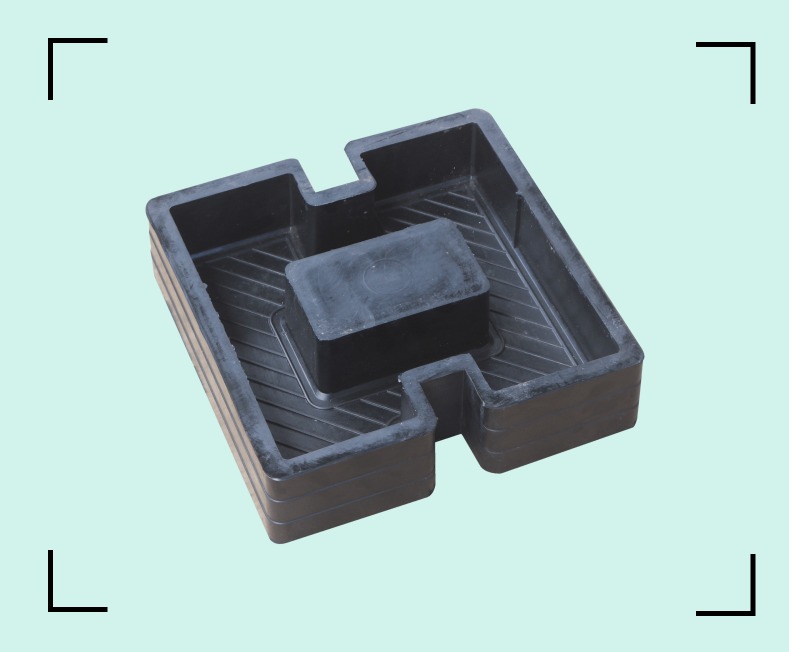

Top Quality Compound wall Mould – Rubber Mould

JR Rubber Industries manufacture Rubber moulds for precast compound wall in a wide range of designs and sizes.We manufacture Rubber moulds precast boundary wall panels, Rubber moulds for poles,Coping moulds,Moulds for boundary wall base and moulds required for all elements of compound wall. All elements of compound walls are precast in factory and are installed at site. Colours and design is inbuilt. Rubber moulds are flexible and easy to demould.This also ensures zero damage production.The production can be done even in a small factory setup and scale upto large production plants for mass production. We have moulds with various designs and textures,mould designs with perforation which are only possible to be casted in Rubber moulds.

Precast boundary walls casted in Rubber moulds have unmatched finishing,glossy finish. The moulds with concrete mix are Vibro formed which gives the concrete products high strength. Reinforcements and Glass fiber can be included in admixture to improve strength of panels.

Our products range from precast compound wall moulds, rcc boundary wall, compound wall mould, readymade compound wall and many more. Compared to stone walls and brick walls, precast compound walls are very cost effective. Beautiful designs can be made with precasting which are impossible with masonry work.

Precast compound walls are a time saver as the installation time is very less. Also, with precast compound walls, the labor cost is less , installations mechanized and faster.

Features:

Easy to cast compound walls.

Easy to de-mould.

Easy installation.

High strength concrete panels can be casted.

Astonishing designs are possible.

Rubber moulds when vibro-formed gives the panels glazing and high aesthetic appeal.

Can be casted even in small factory setup.

The color and design is inbuilt.

Panels are ready to install after production in the factory itself.

Precast compound walls are a time saver as the installation time is very less. Also, with precast compound walls, you can save the labour cost as we will do the installation for you. Our compound walls are also very strong. We export our moulds across the world to countries like Uganda, Kenya, Somalia, Tanzania, Kenya, UAE, Sudan, Zambia, Qatar, Oman, Saudi Arabia, Vietnam, Ethiopia, USA, Cameroon, Bangladesh, Mauritius, Malaysia, Mali, Nepal, etc.

Rubber Mould

PVC Mould

Plastic Mould

Compound Wall

Machinery

Chemical

WALL PANELS

PILLARS

DOMES

COPINGS