The Best Choice Of Paver Block Moulds In Bahrain

Are you looking for high-quality paver block moulds in Bahrain to enhance your construction and landscaping projects? Look no further! At JR Rubber Industries, we offer a wide range of paver block moulds designed to meet the unique needs of construction professionals. Our premium paver block moulds provide durability, versatility, and a touch of sophistication to your paving projects. We will explore the world of paver block moulds, and their various applications.

Product Overview

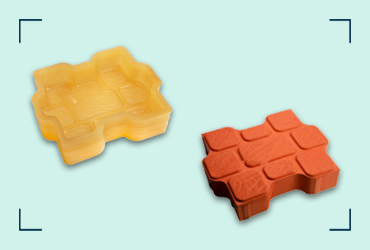

The paver block mould is a special mould used to shape and create paver blocks. These molds help make strong and durable blocks used for making pathways, driveways, and outdoor surfaces. They give the blocks their shape and design, allowing them to fit together neatly like puzzle pieces. These blocks are commonly used in construction and landscaping to create strong and elegant outdoor spaces.

And we have provided three types of paver block moulds such as rubber,plastic and PVC paver block moulds for more landscaping options.

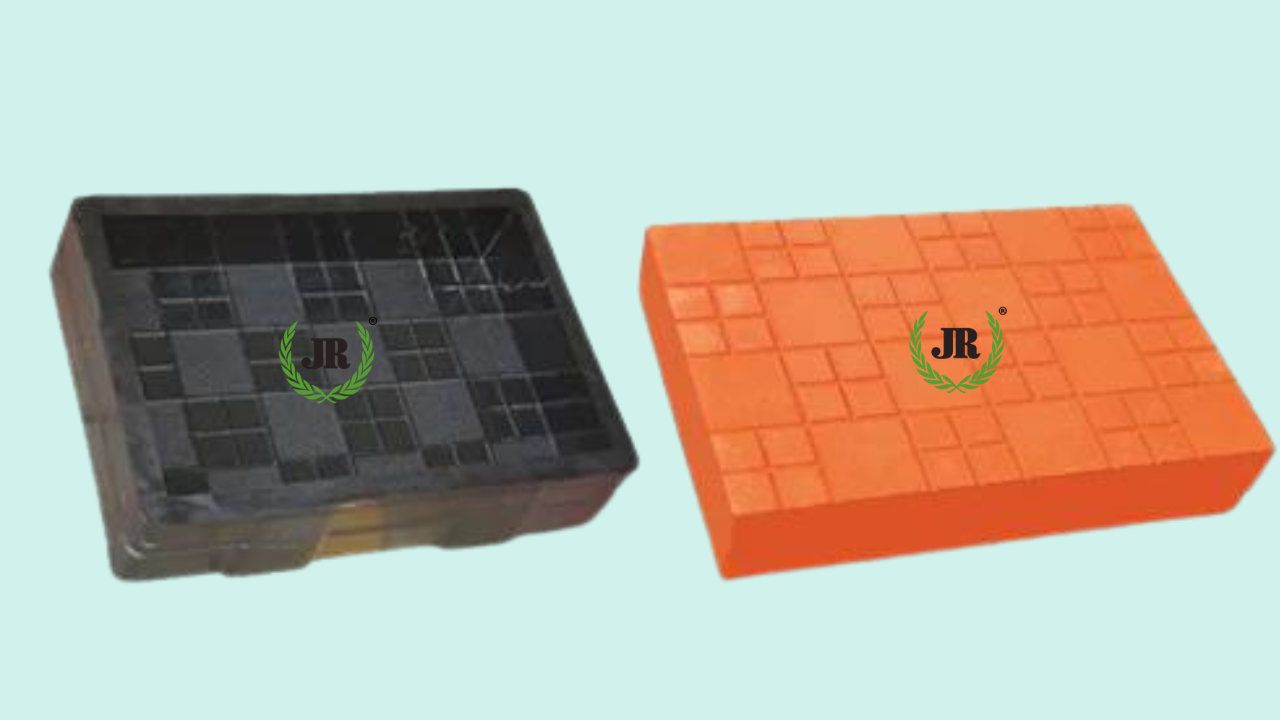

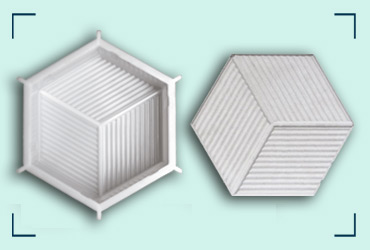

Plastic Paver Block Mould

The paver block moulds are made with high-quality plastic which gives the customer the best option for customised, durable and variety of paver block mould designs.we produce plastic moulds of different shapes and designs, such as the zigzag, I-shape, Hexagon, Squares, T Series, etc.JR molds made of plastic are made with 100% pure material. We manufacture premium plastic paver moulds designed for paver blocks. We present new and unique mould designs every week.

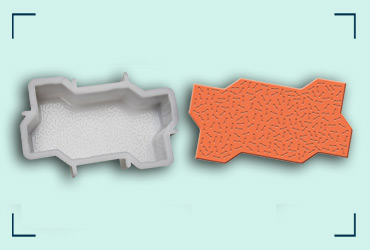

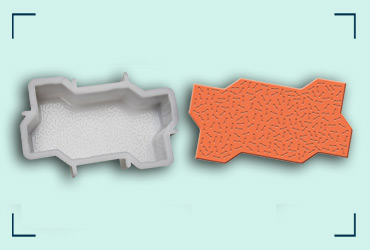

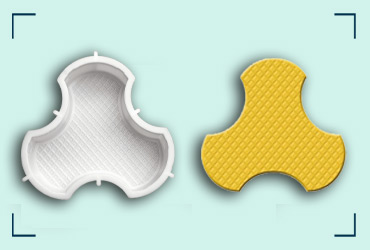

Rubber Paver Block Mould

Rubber paver moulds are used in the production of concrete or cement pavers. These moulds ensure precise and consistent results in the production process.As the name says these moulds are made from rubber materials which make them durable and flexible for repeated use. With JR Rubber Mould’s paver blocks, you can manufacture products of many shapes and styles. Our product range includes square blocks, zigzag blocks, 3D blocks, T series, I series, natural stone designs, dumbbell shapes, and many more. We can also create custom molds and interlocking molds according to your specification.

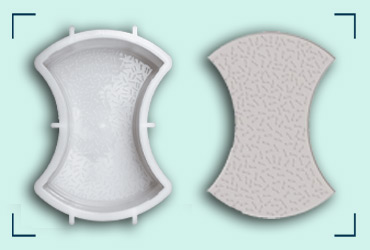

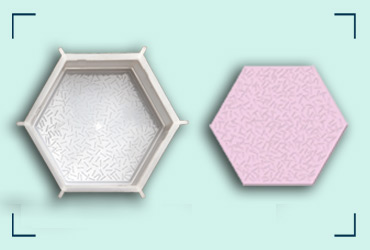

PVC Paver Block Mould

These moulds are specialized molds used in the production of interlocking concrete or cement pavers. They function as templates, giving pavers their shape as well as appearance. The molds are constructed of robust PVC material so that it can be utilized numerous times. PVC material has a flexible structure, which makes it easy to remove the pavers off after they have been formed.

PVC Paver moulds allow the manufacture of perfectly-shaped pavers that are consistent and well-shaped. They can be used to create diverse patterns and designs for the pavers. Paver molds made of PVC are strong and can withstand concrete with ease, making sure that the molds last for an extended period of time.

Key Features Of Our Paver Block Moulds

Consistency

The precision engineering of our paver block moulds ensures that every paver block you create is uniform in size and shape, providing a clean and polished look to your paving bricks.

Durability

Our paver block moulds are crafted from high-quality raw materials that ensure longevity and resilience, even in challenging weather conditions. They are built to withstand the strain of continuous use.

Ease Of Use

Our moulds are designed with the user in mind. They are easy to use, allowing professionals and DIY enthusiasts to create perfect paver blocks without much hassle.

Design Versatility

Our wide range of designs allows you to create captivating patterns and layouts that complement your landscape design.

Why Choose JR Rubber Industries ?

JR Rubber Industries, is a renowned manufacturer of rubber moulds, plastic moulds, and PVC moulds and is also the best seller for paver block moulds in Bahrain. We also provide complete solutions for paver production with machinery, moulds, chemicals, technology, and in-plant training.

You will find various designs for paver block moulds to make your outdoor spaces more elegant and beautiful.Paver block moulds provide design flexibility, and durability in creating custom-designed paved surfaces.

With more than 25 years of experience in this industry, we have established reputed rubber manufacturers. And our commitment to serve quality products to satisfy the customer needs. From small-scale projects to large-scale industrial applications, our team is equipped to handle any challenge and deliver exceptional results.

Our Expert Services

- Design, engineering, supply, and installation of machines

- supply of chemicals and color oxides

- Paver production assistance anywhere in the world

- In-plant training for client personal

- Onsite machinery fabrication and Installation anywhere

- Design and develop customized molds

Case Studies

Having only experience in building construction needed to learn about external paving works as part of my skill development. I chose to learn about Paver Block Moulds from JR Rubber Industries and approached them. During the training period, they were very helpful in explaining in detail the manufacturing process and also received hands-on experience in the whole operation. By the end of the training, I was confident to start a new venture myself. The Management allocated their valuable time and resources and I am very grateful to them. It was an enjoyable experience.

As a Contractor for a big resort chain, with a large external development in hand I knew it would be a great challenge. One of my friends suggested JR Rubber Industries as a reliable supplier for the Paver supply. I got all the required information to set up the plant locally and imported all the machinery, moulds, and raw materials required for paver production. I am happy I chose JR Rubber Industries as all their shipments arrived on time. They also send their technicians to train our staff. Overall the whole project was completed in time and the Client was impressed with our work. I thank all those in JR for their support and guidance.

How To Order

To order our Plastic Paver Block Moulds in Bahrain, you may visit our website at or click the Contact Us button below.

Frequently Asked Questions

1) What types of paver block moulds do you offer?

We offer a wide range of paver block moulds in various shapes, sizes, and designs to suit different construction and landscaping needs.

2) What materials are available for paver block moulds?

We provide paver block moulds in different materials, including rubber, plastic, and more. The choice of material depends on your project’s needs.

3) Do you provide delivery services in Bahrain?

Yes, we offer reliable delivery services in Bahrain to ensure your paver block moulds reach your project site on time.