Cover Block

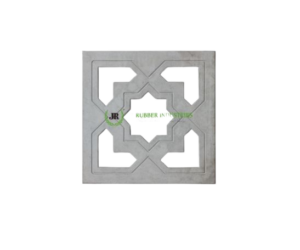

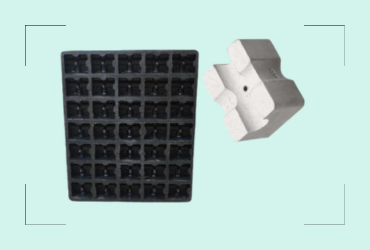

Cover Block Rubber Mould Designs

COVER BLOCK 1

View More

Enquiry

COVER BLOCK 2

View More

Enquiry

COVER BLOCK 3

View More

Enquiry

COVER BLOCK 4

View More

Enquiry

COVER BLOCK 5

View More

Enquiry

COVER BLOCK 6

View More

Enquiry

COVER BLOCK 7

View More

Enquiry

COVER BLOCK 8

View More

Enquiry

COVER BLOCK 9

View More

Enquiry

COVER BLOCK 10

View More

Enquiry